Refractory Castable

Refractory Castable Specification

- Feature

- Good Quality

- Condition

- New

- Usage

- Industrial

- Type

- Refractory Castables

- Product Type

- Refractory Castables

- Warranty

- 1 year

Refractory Castable Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Delivery Time

- 5-10 Days

About Refractory Castable

Refractory castable is a type of heat-resistant material composed of a mixture of refractory aggregates, binders (like calcium aluminate cement), and additives. It is supplied in dry form and becomes a dense, durable material when mixed with water and cast into place. Refractory castables are used to line high-temperature equipment such as furnaces, kilns, and incinerators, offering excellent resistance to heat, abrasion, and thermal shock.Premium Industrial Refractory Castable

Engineered for optimal performance, our refractory castable serves a wide range of industrial uses such as lining furnaces, kilns, and reactors. With a focus on durability and efficiency, it provides exceptional resistance to heat and abrasion, ensuring longer operational life. This product is meticulously manufactured in India and is supported by a reliable export and supply chain network, assuring consistent quality for our global clients.

Reliable Quality with Guaranteed Assurance

Featuring robust compressive strength and excellent thermal stability, our refractory castable undergoes stringent quality checks before dispatch. This not only guarantees good quality but also secures consistent performance in even the harshest conditions. The product is covered by a 1-year warranty, offering peace of mind and enhanced value for industrial buyers.

FAQ's of Refractory Castable:

Q: How should I apply the refractory castable in industrial equipment?

A: To use the refractory castable, mix it with clean water as instructed and apply to the prepared surface of your furnace or kiln. Use standard casting or gunning methods, ensuring the material is evenly distributed and adequately compacted for a lasting hold.Q: What benefits does this refractory castable provide compared to traditional materials?

A: Our refractory castables offer superior thermal shock resistance, good quality, and a longer lifespan. They provide simplified installation and maintenance, helping reduce downtime and operating costs for industrial processes.Q: When is the optimal time to install refractory castables in industrial settings?

A: It is best to install refractory castable during equipment shutdowns or scheduled maintenance periods. This allows for proper curing and ensures the castable achieves its full strength before being subjected to high-temperature operations.Q: Where is this refractory castable manufactured and supplied from?

A: This product is manufactured in India by a reputable company that functions as an exporter, manufacturer, and supplier, ensuring direct and efficient supply across industrial markets globally.Q: What is the process for curing the refractory castable after installation?

A: After application, the refractory castable should be kept damp for at least 24 hours to facilitate initial curing. It should then be dried at ambient temperature before gradually heating the equipment, allowing the castable to develop maximal strength without cracking.Q: How does the 1-year warranty on the refractory castable provide value to industrial users?

A: The 1-year warranty covers any manufacturing defects, giving buyers assurance of product quality and protection. This support reduces operational risk and underlines our commitment to delivering reliable industrial materials.Q: What industrial sectors commonly use this specific type of refractory castable?

A: This refractory castable is widely used in industries such as steel, cement, petrochemicals, and power generation, where high-temperature and abrasion-resistant linings are critical for efficient and safe operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Melting Furnace Accessories Category

Ceremic Screw

Price 65.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Condition : New

Usage : Melting Furnace

Size : 150mm

Type : spring type

Hearth Plate For Heat Treatment Furnace

Price 1800 INR / Piece

Minimum Order Quantity : 5 Pieces

Condition : New

Usage : Other, For Heat Treatment Furnace

Size : Customizable or as per requirement

Type : Hearth Plate

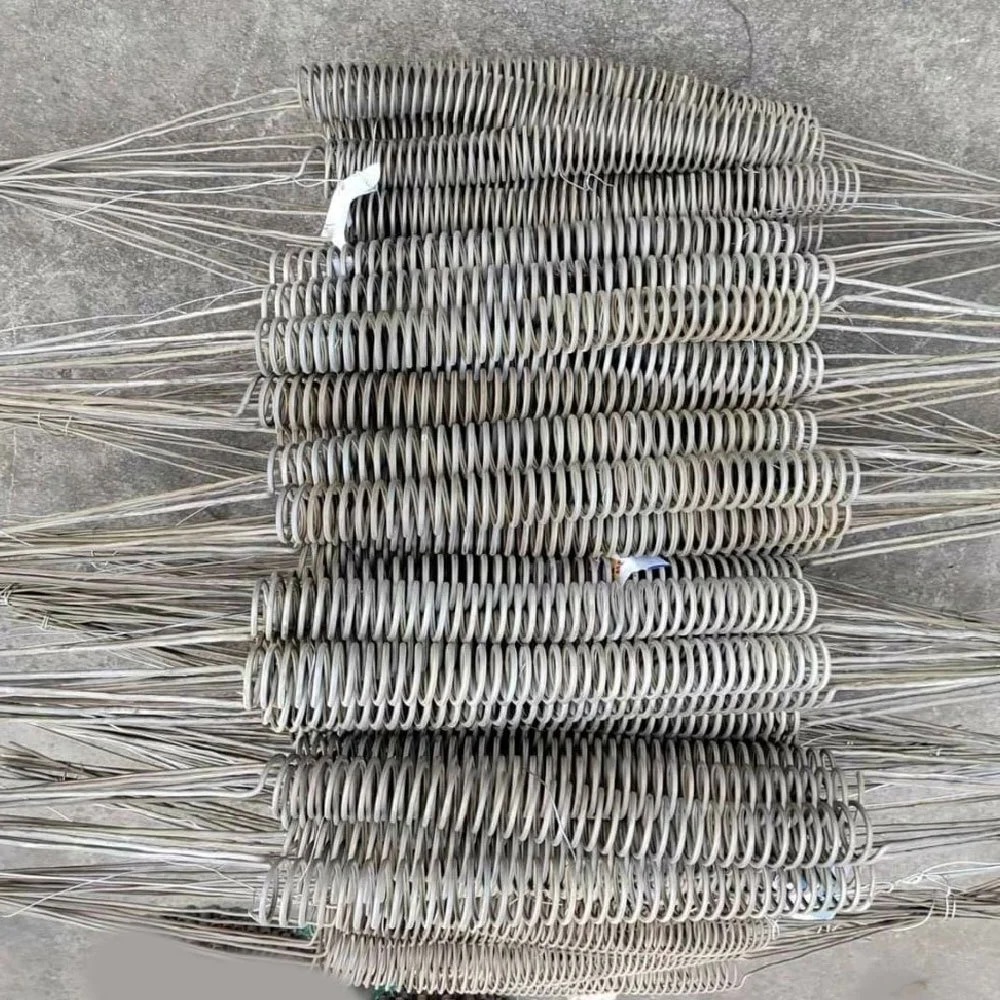

Coil Heater

Price 1200.0 INR / Number

Minimum Order Quantity : 10

Condition : New

Usage : Industrial

Size : Standard

Type : Coil Heater

Ceramic Blanket

Price 800.0 INR / Unit

Minimum Order Quantity : 1 Piece

Condition : New

Usage : Heat Treatment furnace

Type : Blanket